Transfer case Pt 3

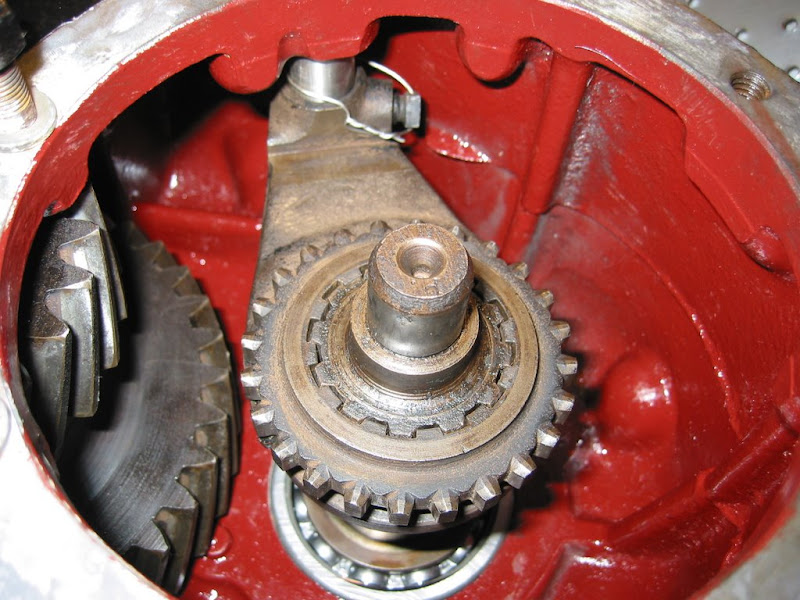

While waiting for the idler shaft tool I'll been cleaning and prepping the other parts of the case.

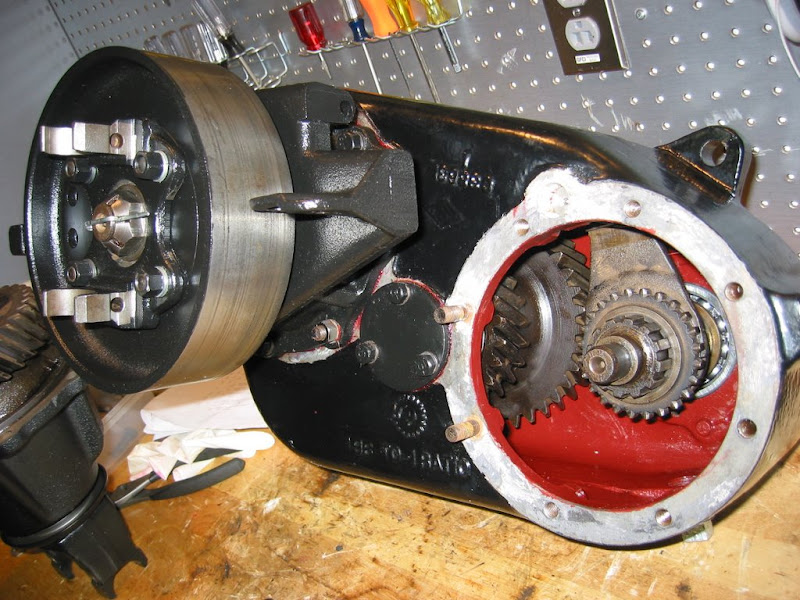

I'll probably have to take the case somewhere to have it blasted and painted or powder coated. While I could get the case in my oven I can't fit it into my blast cabinet. But first I need a lot of de-greaser and scrubbing to get rid of 60 years of leaking lube oil.

In the mean time all the parts are on order so once the case is cleaned and finished I can start re-assembly. But first some vacation time with my family.

Have a good week all.

While waiting for the idler shaft tool I'll been cleaning and prepping the other parts of the case.

I'll probably have to take the case somewhere to have it blasted and painted or powder coated. While I could get the case in my oven I can't fit it into my blast cabinet. But first I need a lot of de-greaser and scrubbing to get rid of 60 years of leaking lube oil.

In the mean time all the parts are on order so once the case is cleaned and finished I can start re-assembly. But first some vacation time with my family.

Have a good week all.

Comment