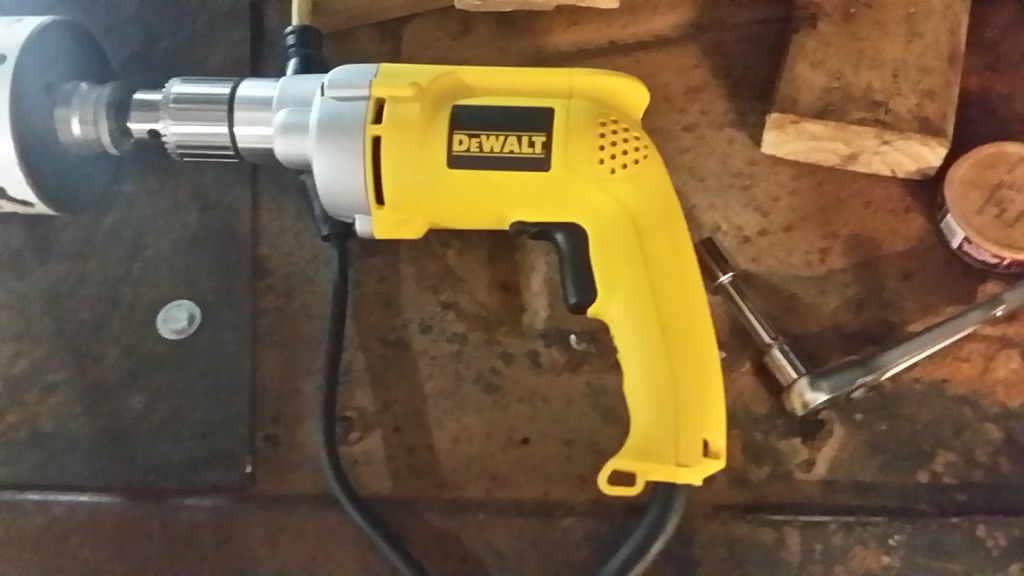

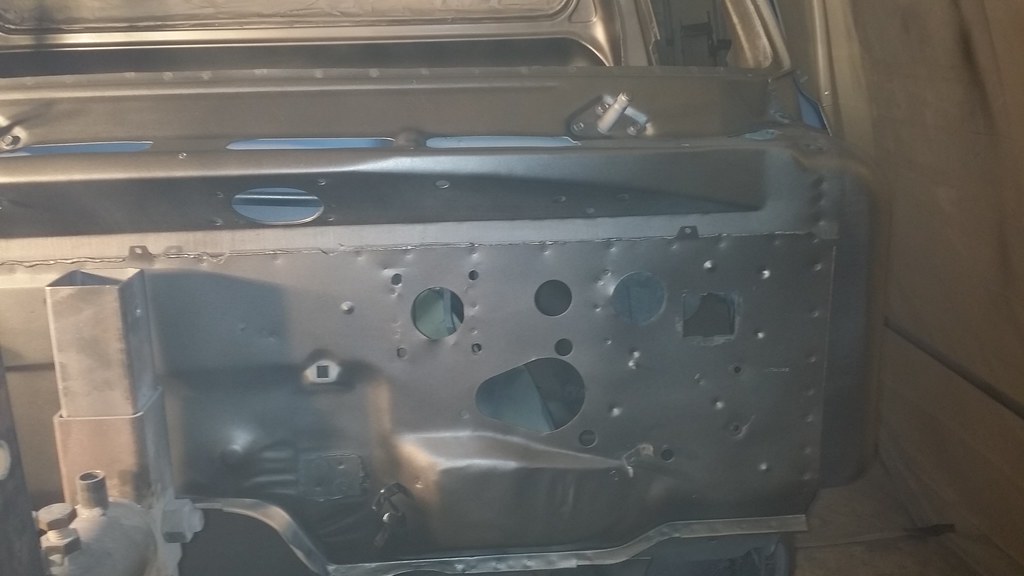

Not a lot accomplished tonight, managed to get the 6 - 1/2" diameter holes drilled through the frame on the front to mount my tow bar. Need to pickup some 4" long grade 8 bolts tomorrow to get it mounted permanently. Was going to attempt to suck out some mud from inside the frame as well and ended up screwing with my shop vac as it's low on suckage. So along with the bolts, I've got to pick up a new filter for it too.

Comment