I started the front differential on the Red 46 PW draining yesterday. Did you know the 46 drain plug is a small 1/4" pipe plug with the letters US stamped on the face? Since it was going to take a while I let it drip overnight.

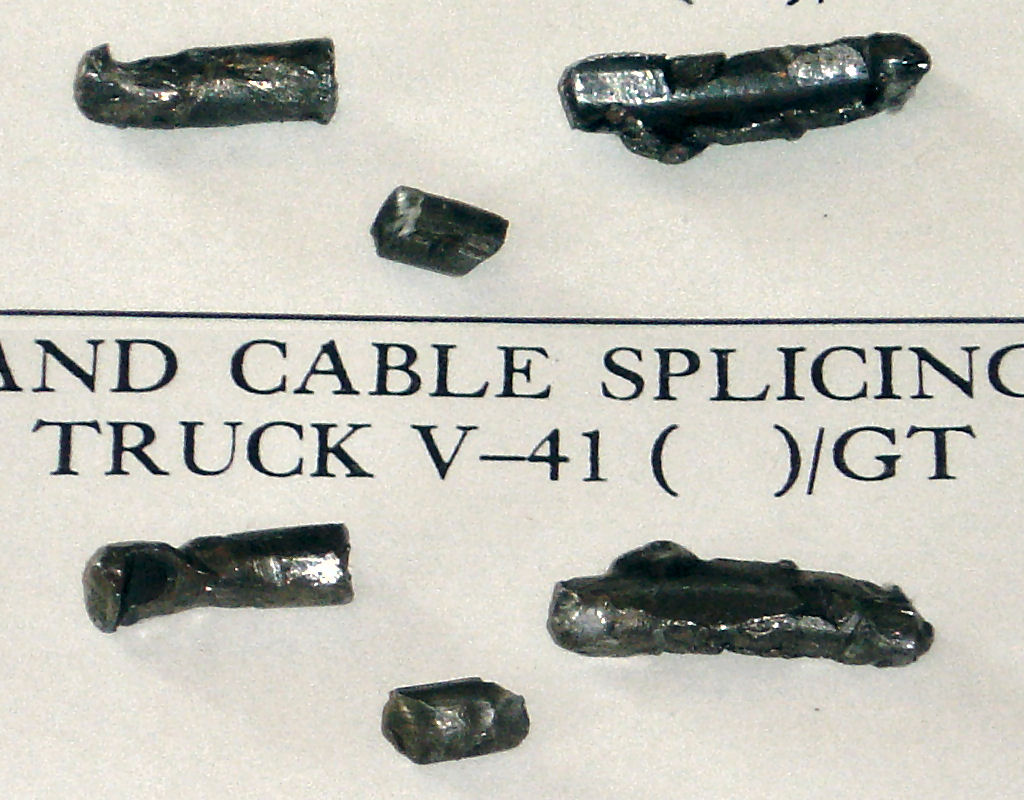

When I got into the shop this afternoon, I found a small metal dowel like pin (lower piece in the picture) with angle sheered ends, and three groves cut the length of it laying on the top of the oil pan.

So I pulled the differential out (had planned on doing it anyway) and found two more large pieces, but nothing small and no shavings. One looks line the rest of the metal dowel, and the other might have been e piece that was smashed between the gears.

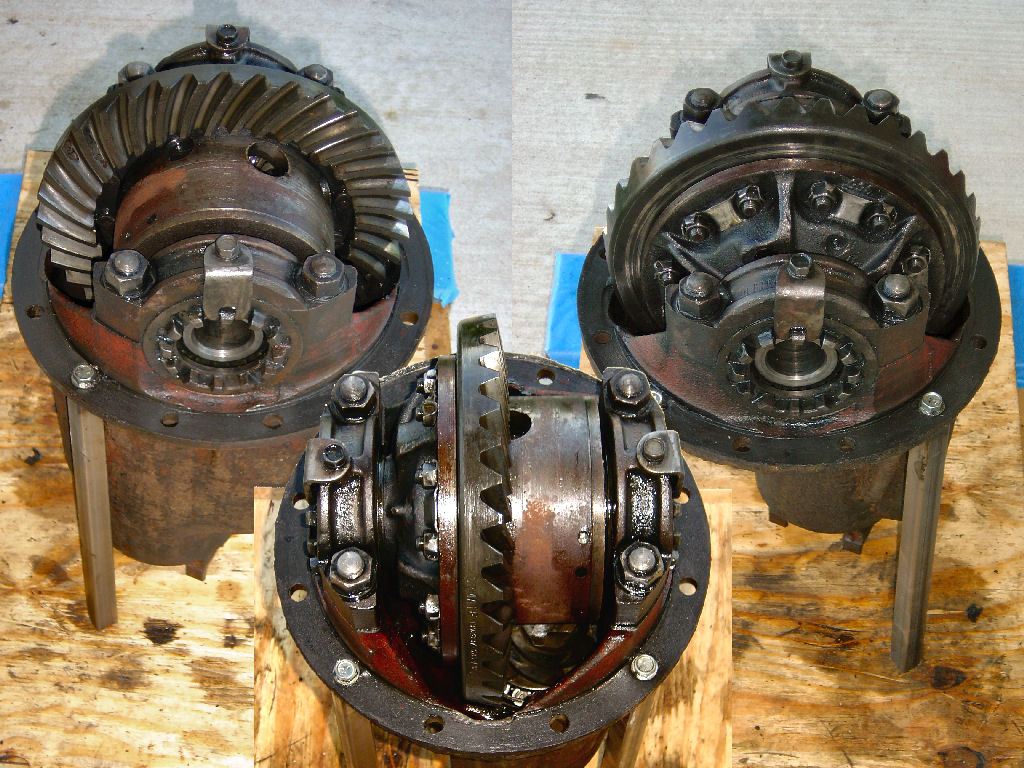

I've looked over the differential visually and found no issues problems or missing pieces. It turns great with a little back lash slop.

Have I found remnants of a previous broken deferential, or is there a part inside the carrier that I can see than might have come out?

Comment