I have started the tear down of my 1953 m37 project, the "bulldog".

I have the cab, bed and engine off of the frame.

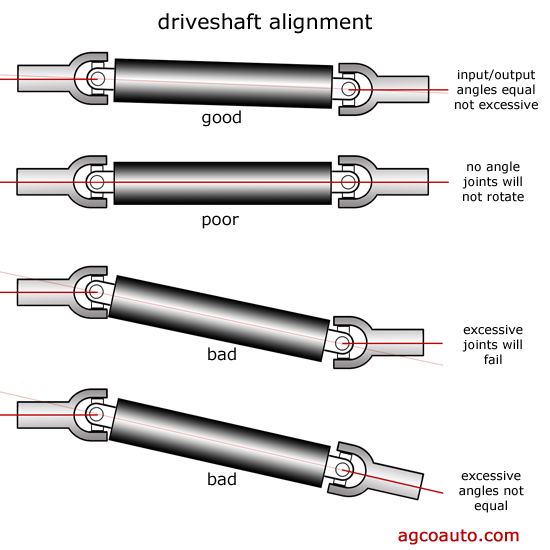

I have a centered rear from a WC truck to use on it, with the axles. I noticed that the driveshaft angle from the NP 200 TC back to the stock diff is relatively steep. I noted that the ebrake output (center) shaft on the TC is an inch or two higher than the stock side shaft going back.

Is the additional angle that will result a potential problem here?

I have the cab, bed and engine off of the frame.

I have a centered rear from a WC truck to use on it, with the axles. I noticed that the driveshaft angle from the NP 200 TC back to the stock diff is relatively steep. I noted that the ebrake output (center) shaft on the TC is an inch or two higher than the stock side shaft going back.

Is the additional angle that will result a potential problem here?

Comment