Figured I'd start a thread on the W300M that I'm in the midst of restoring. This was originally going to just be a parts truck, but I've decided not to throw in the towel. This truck came out of Northern California (I'm in Salt Lake City), and is remarkably rust free, but at some point in its career had something very heavy slam into the cab above the passenger side door. It not only crushed the cab, it also bent the arch above the door (but didn't bend the door itself, which makes me think the door was open when the dent occured) The door would not even come close to shutting. In addition to the large dent in the cab, the entire top of the cab was flattened...too many heavy things thrown across the top of the cab over the years. First order of business was to crib up the cab with some 4x4's, and then I pressed the door arch back into shape with a 25 ton bottle-jack. Lots of hammer & dolly work, followed by some hand-held English-wheeling with a cheapo Harbor Freight benchtop model that I modified, and the cab is getting to the point where it's almost presentable.

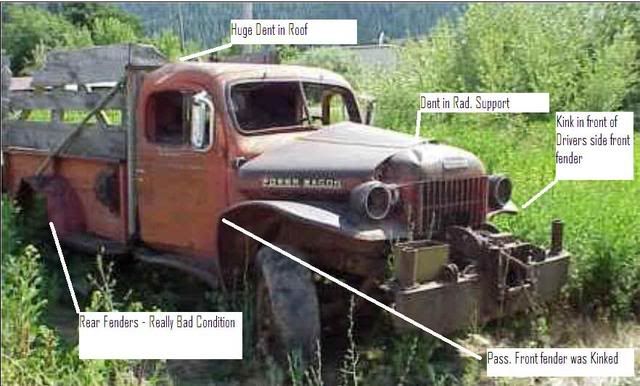

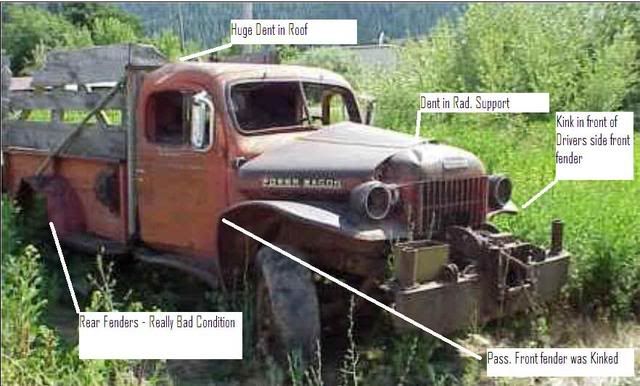

Here's what it looked like before:

Here's a shot of the my "handheld" English Wheel being used. Works surprisingly well, and my neighbors like it better than the planishing hammer!

Here's where I am now. No big dents, and the English Wheel "re-arched" the flattened cab nicely! Just some Rustoleum sprayed on for protection right now. I should be ready to put down some primer this spring.

Here's what it looked like before:

Here's a shot of the my "handheld" English Wheel being used. Works surprisingly well, and my neighbors like it better than the planishing hammer!

Here's where I am now. No big dents, and the English Wheel "re-arched" the flattened cab nicely! Just some Rustoleum sprayed on for protection right now. I should be ready to put down some primer this spring.

Comment