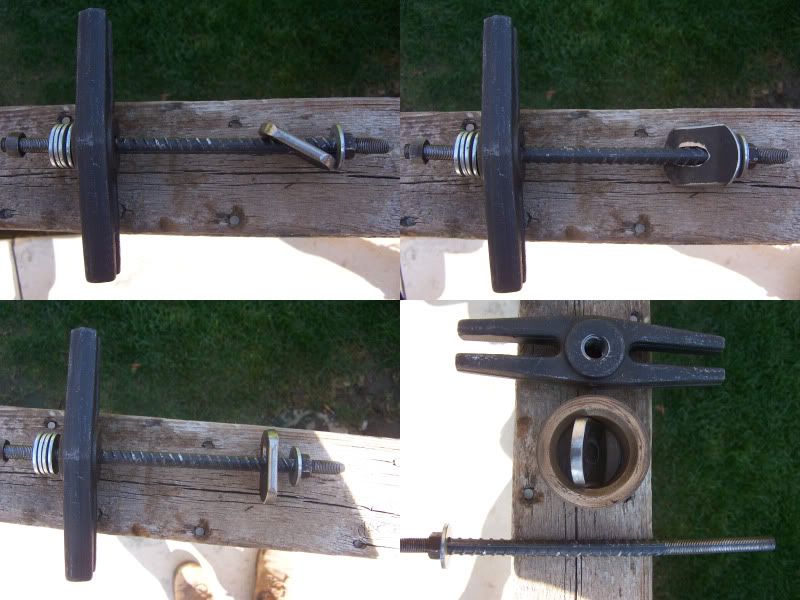

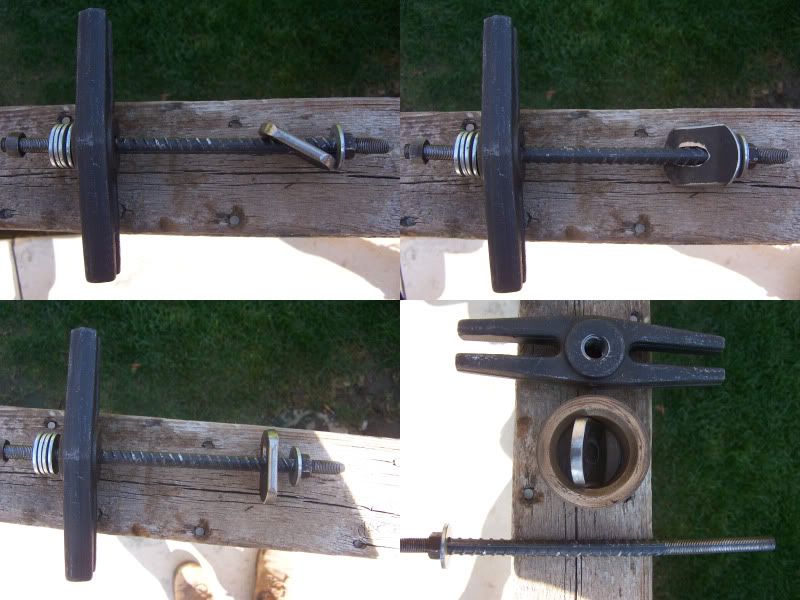

There have been a couple posts on this, and I got the idea from Johns S. (thanks!). I figured I'd share the version that I came up with in case someone out there needs a cheap, easy to make puller. I had some 3/8 rebar laying around, and threw some threads on it. The washer with the flats is made out of some 1/4 plate with a 3/8 diagonal hole drilled through it. I used part of my split bearing puller to go across the bell.

Comment