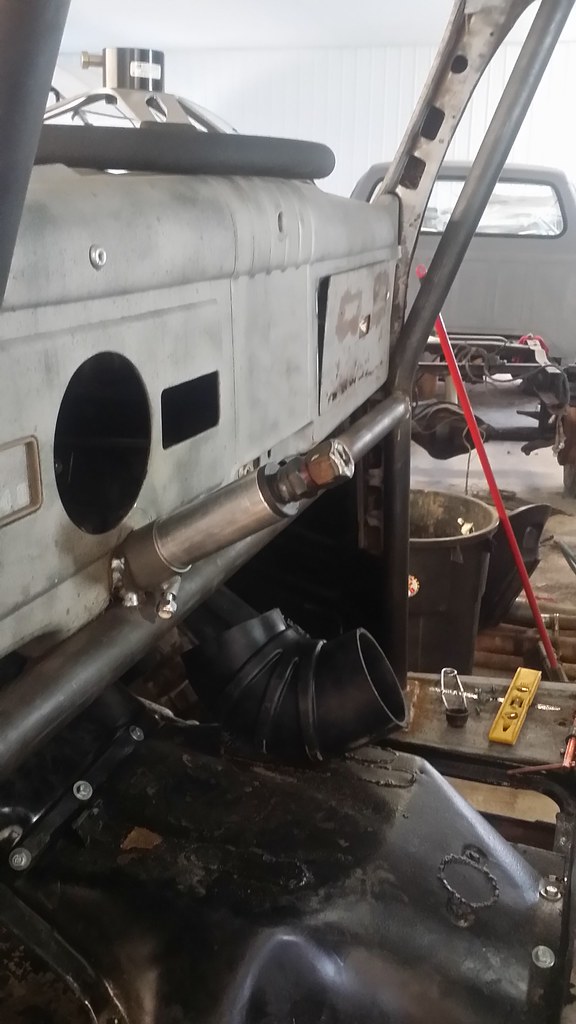

Not much accomplished today, was tired and sore from yesterday. But I cut the areas out on both floor boards where the roll cage kept them from fitting flat. Just need to put some por 15 on the edges where I cut them to seal them up.

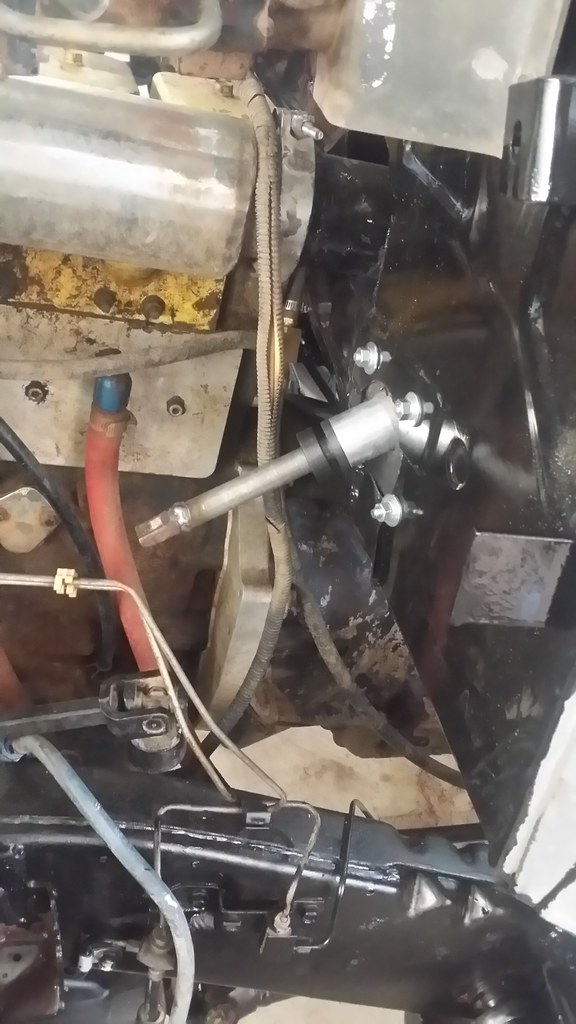

Mounted the transmission dipstick, starter solenoid, and the 70 amp fuse I use for the up circuit of the fuel shut off solenoid. Prepped my battery boxes, shut off switch tab and the inner c of my rear frame, rear drive shaft and center section of the rear end to be coated in Chassis black tomorrow night when I get home.

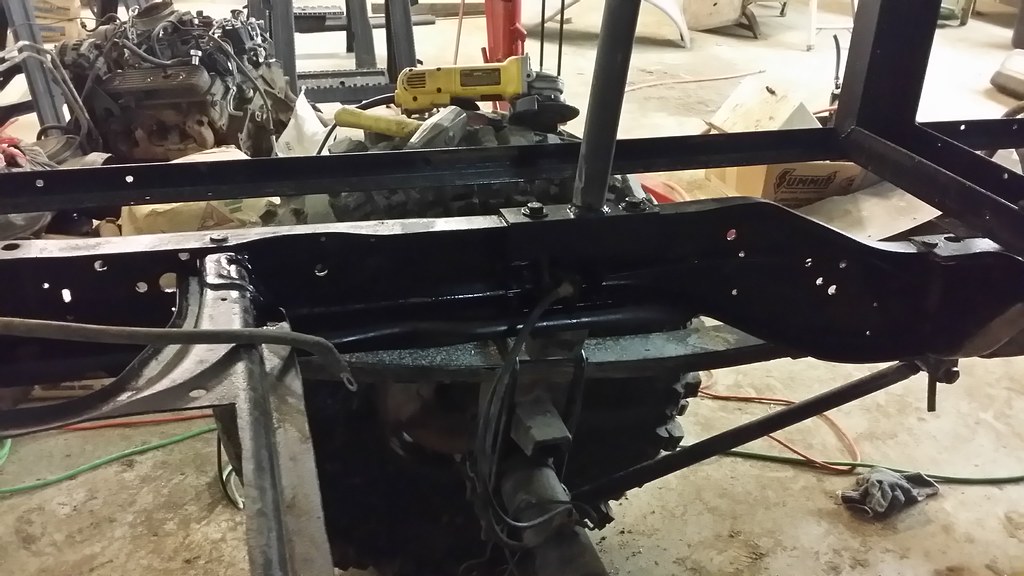

I also closed up the front of the frame where my tow bar enters it so there isn't a huge gaping hole there. The front boxed frame is now ready to be filled with foam to keep it from getting filled up with mud again. Then I will get the front frame painted next.

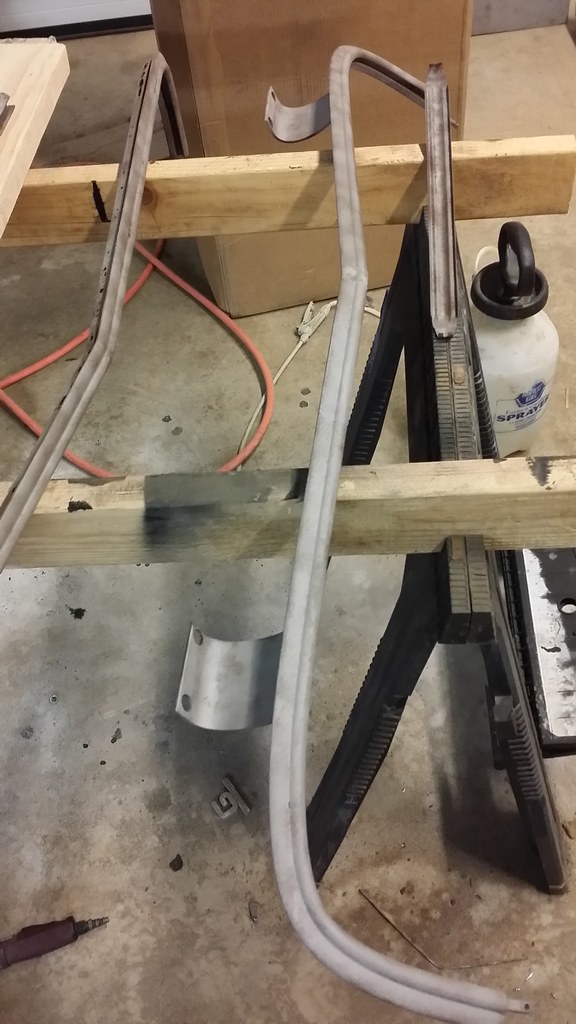

I also drilled and bolted the rear portion of the cage to the frame, and have all but the frame portion of the holes drilled in the cab to go to the frame on the back of the cab, but I have to get a longer 1/2" drill bit, mine wasn't long enough and I need to pickup 2 longer grade 8 bolts.

Mounted the transmission dipstick, starter solenoid, and the 70 amp fuse I use for the up circuit of the fuel shut off solenoid. Prepped my battery boxes, shut off switch tab and the inner c of my rear frame, rear drive shaft and center section of the rear end to be coated in Chassis black tomorrow night when I get home.

I also closed up the front of the frame where my tow bar enters it so there isn't a huge gaping hole there. The front boxed frame is now ready to be filled with foam to keep it from getting filled up with mud again. Then I will get the front frame painted next.

I also drilled and bolted the rear portion of the cage to the frame, and have all but the frame portion of the holes drilled in the cab to go to the frame on the back of the cab, but I have to get a longer 1/2" drill bit, mine wasn't long enough and I need to pickup 2 longer grade 8 bolts.

Comment